Welcome to the Irish Mini Owners Club Forum. Keep an eye out of on coming events!!!!

1275GTi conversion

Moderators: spud1979, The Marcos Graveyard, Moderators

- CLUBMANGT

- NON Member

- Posts: 1076

- Joined: Fri Oct 23, 2009 8:59 pm

- Whats your location?: Leopardstown

- Region: Eastern

- What Minis have you?: 86 Mayfair 1000GT

- Modifications: 1275 and bar the shell and subframes new everything!! IMOC MEMBER

- Location: Leopardstown

- Contact:

Re: 1275GTi conversion

I like the way you make it up as you go along Aidan  thats my kind of spannering . nice work keep it up, and all us updated .

thats my kind of spannering . nice work keep it up, and all us updated .

ALL YOU NEED IS POWER AND LOADS OF IT!!!

-

desmoben1

- NON Member

- Posts: 12

- Joined: Fri Nov 12, 2010 9:47 pm

- Whats your location?: Co. Louth/Dublin

- Region: Eastern

- What Minis have you?: 1976 Clubman 1100

1973 Innocenti Cooper 1300 Export...what have I started??? - Modifications: ..they're both works in progress

Re: 1275GTi conversion

Will look forward to seeing the finished article.

Keep up the good work!

Keep up the good work!

No no no baby - Its not a "money pit"....its a "mini pit"!

- BERT

- NON Member

- Posts: 485

- Joined: Tue Jun 16, 2009 2:48 pm

- What Minis have you?: Mini miglea 1480cc

81' clubby estate - Location: Greystones,co Wicklow

- Contact:

Re: 1275GTi conversion

A set of 100+ wheels would look great on this!

- Tony Cooney

- NON Member

- Posts: 1324

- Joined: Fri Dec 05, 2008 11:44 pm

- Whats your location?: Dublin

- Region: Eastern

- What Minis have you?: 1992 Mini City

- Location: Lucan

- Contact:

Re: 1275GTi conversion

Only getting to see this thread now........

Looks great and a LOT of dedicated skilled work there.

Now I know the REAL reason you have Thursdays free!!!!!!!!

Tony

Looks great and a LOT of dedicated skilled work there.

Now I know the REAL reason you have Thursdays free!!!!!!!!

Tony

-

seanos

- NON Member

- Posts: 360

- Joined: Thu Jun 11, 2009 11:55 pm

- Whats your location?: Firhouse

- Region: Eastern

- What Minis have you?: '90 mini 998cc

- Modifications: Straight through exhaust, bucket seats stage 1, 12x6 matt black revo's, matt black paint job(work in progress)

- Location: Firhouse

- Contact:

Re: 1275GTi conversion

Its sound deadening I think Seanos........you would think with all the sound deadening he would want a quiet car

And I said, Officer, I didn't want to be drunk in public...I wanna be drunk in the bar. Now last time I checked it was still legal to be drunk in the bar. They threw me into public...arrest them!

-

kerryminigringo

- IMOC Paid Member

- Posts: 2680

- Joined: Thu Feb 10, 2005 9:44 pm

- Whats your location?: Between an A series and a G13B

- Region: Eastern

- What Minis have you?: 61 van,68 MKII,

75 Clubman estate,

80 1275GT

91 RSP Cooper - Location: Between an A series and a G13B

- Contact:

Re: 1275GTi conversion

Yes it is sound deadening.It is on every flat panel on the interior of the car to reduce noise levels.I will also be putting sound deadening underlay under the carpet as I want to have as quiet a Mini as possible. I had hoped to get the air filter moved towards the front of the engine bay but space will not permit this to reduce induction noise.

Real Clubmans have a square nose.Seriously.

-

spicooper

- Comittee Member

- Posts: 186

- Joined: Thu Apr 19, 2007 8:42 pm

- Whats your location?: Naas

Kildare - Region: Eastern

- What Minis have you?: 1980 Mini Specical

1979 1000 Saloon

1994 spi cooper - Contact:

Re: 1275GTi conversion

Great work love the colour scheme real old school. Can’t wait to see it on the road.

Cheers Spicooper

________________________________

Rust is not a problem but an opportunity to weld.

Cheers Spicooper

________________________________

Rust is not a problem but an opportunity to weld.

-

nearlythere

- NON Member

- Posts: 47

- Joined: Tue Aug 22, 2006 10:46 pm

- Contact:

Re: 1275GTi conversion

Aidan!!

Logged on for the first time in a wee while - WOW

a personalised wow!! looking good - haven't been in touch in yonks. Hope you and the gang are all keeping well. I still haven't bought another mini, practicality has outweighed my love for them for the time being. Not to say that im not constantly on the lookout for something new in the for sale sections!

looking good - haven't been in touch in yonks. Hope you and the gang are all keeping well. I still haven't bought another mini, practicality has outweighed my love for them for the time being. Not to say that im not constantly on the lookout for something new in the for sale sections!

Conor

Logged on for the first time in a wee while - WOW

a personalised wow!!

Conor

i want one now

- StanO'Toole

- NON Member

- Posts: 2244

- Joined: Tue Mar 24, 2009 7:40 pm

- Whats your location?: South Dublin

- Region: Eastern

- What Minis have you?: 1995 Mini Mayfair

1994 Mini Sprite - Contact:

Re: 1275GTi conversion

Getting old is a must but growing up is optional!

StanO'Toole

StanO'Toole

- joebe1

- NON Member

- Posts: 1081

- Joined: Mon Jan 15, 2007 12:41 am

- Whats your location?: Carrick on shannon

- Region: Western

- What Minis have you?: 1980 mini saloon (fip) 1275cc

1969 Clubman gt historic rally car, 1380 c/r s/c dog box, split 45 webbers

1980 irish clubman estate

1969 mk2 retro rally car 1293 s/c gearbox - Location: roscommon

- Contact:

Re: 1275GTi conversion

Poor van

-

kerryminigringo

- IMOC Paid Member

- Posts: 2680

- Joined: Thu Feb 10, 2005 9:44 pm

- Whats your location?: Between an A series and a G13B

- Region: Eastern

- What Minis have you?: 61 van,68 MKII,

75 Clubman estate,

80 1275GT

91 RSP Cooper - Location: Between an A series and a G13B

- Contact:

Re: 1275GTi conversion

Through lack of motivation and a cold garage I have not done much with the GT but I made a start on the wiring.The Mini loom will run the basic stuff so I started by taking out stuff that I would not be using like brake fluid level warning and existing alternator wiring as I am changing this.I decided to mount the new fuse box and relay box on the bulkhead so I made up a plate to cover the hole.

I then drilled and tapped the plate to mount the box and painted it java green using rattle cans.It is a near enough match and it will not be seen anyway.I used a foam draught strip around the plate.

This is the plate in place with the box on the bulkhead.The wires will be connected at the rear and exist the bulkhead over at the drivers side.

I am using relays for the front lights as I intend on putting Cibie Oscars on in the future(colour coded of course) and also relays for the fuel pump.I put as much of the bridging pieces into the box before I mounted it in place.Bit of a snakes wedding but I think I know whats going on.

I also made up a gasket to go between the box and the plate.I made this up with some cork gasket paper I had.I had to build it up at the sides to close the gap.

I got the rad bracket and fan bracket powder coated and I used some hose to plumb it in.The fan will be controlled by a switch in the radiator and also have a backup switch on the dash.Here it is without the hoses fitted.

One problem I had with the rad was the overflow pipe was pointing straight at the inner wing so I had to get the filler taken off and moved 90 degrees to allow the expansion pipe to be fitted.Nothing is easy with this build.

I then drilled and tapped the plate to mount the box and painted it java green using rattle cans.It is a near enough match and it will not be seen anyway.I used a foam draught strip around the plate.

This is the plate in place with the box on the bulkhead.The wires will be connected at the rear and exist the bulkhead over at the drivers side.

I am using relays for the front lights as I intend on putting Cibie Oscars on in the future(colour coded of course) and also relays for the fuel pump.I put as much of the bridging pieces into the box before I mounted it in place.Bit of a snakes wedding but I think I know whats going on.

I also made up a gasket to go between the box and the plate.I made this up with some cork gasket paper I had.I had to build it up at the sides to close the gap.

I got the rad bracket and fan bracket powder coated and I used some hose to plumb it in.The fan will be controlled by a switch in the radiator and also have a backup switch on the dash.Here it is without the hoses fitted.

One problem I had with the rad was the overflow pipe was pointing straight at the inner wing so I had to get the filler taken off and moved 90 degrees to allow the expansion pipe to be fitted.Nothing is easy with this build.

Real Clubmans have a square nose.Seriously.

- woody

- IMOC Paid Member

- Posts: 2838

- Joined: Mon Feb 07, 2005 11:55 pm

- Whats your location?: Drogheda

- Region: Eastern

- What Minis have you?: Traveller

Turbo

Hornet

Equinox

MINI Clubman - Location: LOUTH

- Contact:

Re: 1275GTi conversion

You can order that 2 core rad with the pipe facing the opposite way.

TECHNICAL MODERATOR

- keith

- NON Member

- Posts: 2118

- Joined: Tue Jul 18, 2006 11:15 pm

- Whats your location?: Dún Laoghaire, Dublin

- Region: Eastern

- What Minis have you?: '93 SPi cooper

- Location: Dún Laoghaire, Dublin

- Contact:

Re: 1275GTi conversion

lovely work as always, Aidan. like the idea of extra fuse box & relays.

did you consider a non-mini rad for the front? i'm still looking for a nice fitting one. i haven't tried the metro type which is supposed to fit. I saw a really neat install in germany, essentially the central strut for the slam panel was replaced by a curved piece, now bolted in place, that allowed a rad (think it was custom) fit most of the way across behind the grille.

another thing that i miss is the passenger side fresh air intake....

did you consider a non-mini rad for the front? i'm still looking for a nice fitting one. i haven't tried the metro type which is supposed to fit. I saw a really neat install in germany, essentially the central strut for the slam panel was replaced by a curved piece, now bolted in place, that allowed a rad (think it was custom) fit most of the way across behind the grille.

another thing that i miss is the passenger side fresh air intake....

Signature still awaiting top-coat and lacquer....

-

kerryminigringo

- IMOC Paid Member

- Posts: 2680

- Joined: Thu Feb 10, 2005 9:44 pm

- Whats your location?: Between an A series and a G13B

- Region: Eastern

- What Minis have you?: 61 van,68 MKII,

75 Clubman estate,

80 1275GT

91 RSP Cooper - Location: Between an A series and a G13B

- Contact:

Re: 1275GTi conversion

I had intentions of fitting a Fiat Cinquecento rad and even removed the front slam panel support and made up a smaller one so the rad would fit but when I had all that done I found there was not enough clearance between the rad and the outlet manifold so I used a 2 core Mini one instead but I still got to use the Fiat fan.I will not have a fresh air vent on either side.Rad blocks it on one side and the twincam head is on the other.

Real Clubmans have a square nose.Seriously.

- keith

- NON Member

- Posts: 2118

- Joined: Tue Jul 18, 2006 11:15 pm

- Whats your location?: Dún Laoghaire, Dublin

- Region: Eastern

- What Minis have you?: '93 SPi cooper

- Location: Dún Laoghaire, Dublin

- Contact:

Re: 1275GTi conversion

perhaps you can snake the intakes down to the opening on the valance.. *unless* you are using them for brake cooling ducts...kerryminigringo wrote: .... I will not have a fresh air vent on either side.Rad blocks it on one side and the twincam head is on the other.

Signature still awaiting top-coat and lacquer....

-

kerryminigringo

- IMOC Paid Member

- Posts: 2680

- Joined: Thu Feb 10, 2005 9:44 pm

- Whats your location?: Between an A series and a G13B

- Region: Eastern

- What Minis have you?: 61 van,68 MKII,

75 Clubman estate,

80 1275GT

91 RSP Cooper - Location: Between an A series and a G13B

- Contact:

Re: 1275GTi conversion

Because I am using the GT clock I needed a way of getting the temp gauge to read as the Swift sender goes to the ECU so I decided to locate a Mini temp sender in part of the Suzuki's heater pipe.This is the pipe at the start.

I then drilled a hole in the pipe big enough to fit the tip of the sender in.

I then got a nut that fitted the sender.

And I cut it in half as I want to be able to put a lock nut on the sender.

I then got the half nut braised onto the pipe as MIG welding can sometimes be porous.And this is what the finished job looks like.

I then drilled a hole in the pipe big enough to fit the tip of the sender in.

I then got a nut that fitted the sender.

And I cut it in half as I want to be able to put a lock nut on the sender.

I then got the half nut braised onto the pipe as MIG welding can sometimes be porous.And this is what the finished job looks like.

Real Clubmans have a square nose.Seriously.

-

kerryminigringo

- IMOC Paid Member

- Posts: 2680

- Joined: Thu Feb 10, 2005 9:44 pm

- Whats your location?: Between an A series and a G13B

- Region: Eastern

- What Minis have you?: 61 van,68 MKII,

75 Clubman estate,

80 1275GT

91 RSP Cooper - Location: Between an A series and a G13B

- Contact:

Re: 1275GTi conversion

I had used 10mm threaded bar to get the pedal box height right and now that I was happy with the position I had to make up spacers.I had a piece of 2"x1" box section.

So I got the angle grinder out and I cut 4 pieces 60mm long and painted them black.

As the base plate for the pedal box was only 2.5 mm I decided to double up another plate so I cut another one slightly smaller and using the spot welder I welded it together and ran a bead of weld around the whole plate and after a lick of black paint this is the finished product.

It is hard to make out but this is the pedal box in position with the spacers bolted to the top plate.

So I got the angle grinder out and I cut 4 pieces 60mm long and painted them black.

As the base plate for the pedal box was only 2.5 mm I decided to double up another plate so I cut another one slightly smaller and using the spot welder I welded it together and ran a bead of weld around the whole plate and after a lick of black paint this is the finished product.

It is hard to make out but this is the pedal box in position with the spacers bolted to the top plate.

Real Clubmans have a square nose.Seriously.

-

kerryminigringo

- IMOC Paid Member

- Posts: 2680

- Joined: Thu Feb 10, 2005 9:44 pm

- Whats your location?: Between an A series and a G13B

- Region: Eastern

- What Minis have you?: 61 van,68 MKII,

75 Clubman estate,

80 1275GT

91 RSP Cooper - Location: Between an A series and a G13B

- Contact:

Re: 1275GTi conversion

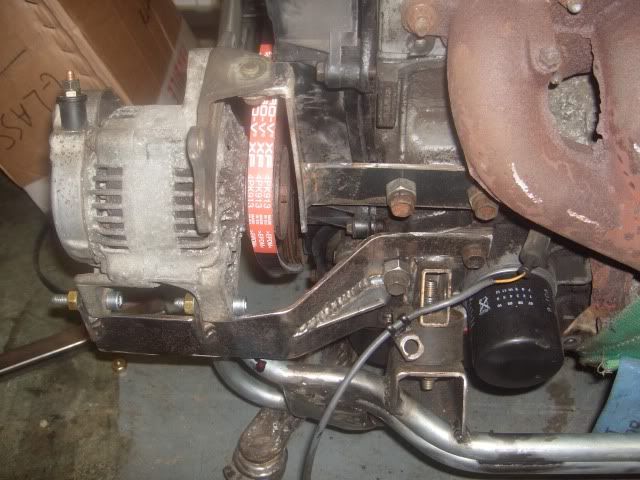

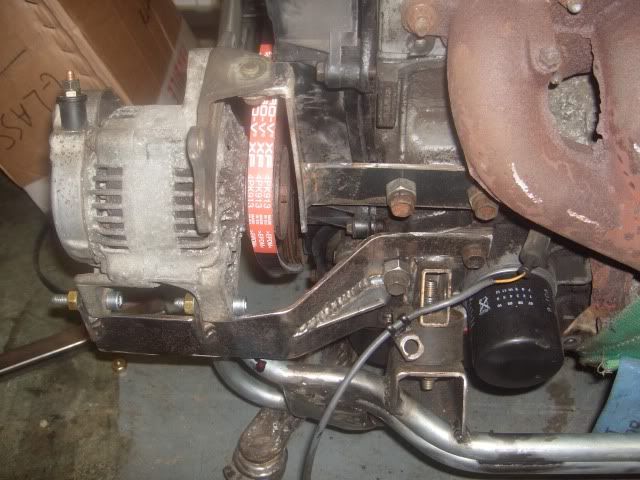

Next up was the alternator mounting bracket.I had made up one earlier but it required piggy backing on an engine mounting which would have made it difficult to put the engine in.Here is the original one I made up.The adjuster bracket which is not shown was also a bit flimsy.

I copied one on 16v Mini forum and it started like this with two mounting tabs for the alternator.I drilled holes to mount it to the block and cut the end at an angle.

I then cut and bent a piece of flat steel so that I could weld it onto the end of the bracket.The reason I had to do this is because if I had used the box section I would not had enough room behind the outlet manifold to use a long bolt so the thin flat steel allows a shorter bolt to be used.

With the bottom bracket sorted I started the adjuster bracket.It will be held on at the side of the 16v head.I cut and drilled a piece of steel to fit two existing holes to form the base plate.

The existing adjuster bracket started out like this.

And ended up like this.

I then got a piece of 1" box section and cut it to lenght to fit the adjuster.I chamfered the box section internally on one end and externally on the other.I cut a piece of 6mm plate stell to fit the box section.

I then welded the 6mm plate to the inside of the box section and ground the weld smooth.I welded the box section to the mounting plate and drilled and tapped an 8mm hole in the centre of the 6mm plate.This is the finished mounting bracket.

And here is the alternator in position,turned 180 degrees so that it fits up under the inner wing.I will fit the engine to the subframe when it is out on the floor and make a cardboard template of the shape that I have to cut from the inner wing so that I can cut it before I fit the engine back in.I also have to cut a small piece out of the cam cover to get it to fit back on.

I copied one on 16v Mini forum and it started like this with two mounting tabs for the alternator.I drilled holes to mount it to the block and cut the end at an angle.

I then cut and bent a piece of flat steel so that I could weld it onto the end of the bracket.The reason I had to do this is because if I had used the box section I would not had enough room behind the outlet manifold to use a long bolt so the thin flat steel allows a shorter bolt to be used.

With the bottom bracket sorted I started the adjuster bracket.It will be held on at the side of the 16v head.I cut and drilled a piece of steel to fit two existing holes to form the base plate.

The existing adjuster bracket started out like this.

And ended up like this.

I then got a piece of 1" box section and cut it to lenght to fit the adjuster.I chamfered the box section internally on one end and externally on the other.I cut a piece of 6mm plate stell to fit the box section.

I then welded the 6mm plate to the inside of the box section and ground the weld smooth.I welded the box section to the mounting plate and drilled and tapped an 8mm hole in the centre of the 6mm plate.This is the finished mounting bracket.

And here is the alternator in position,turned 180 degrees so that it fits up under the inner wing.I will fit the engine to the subframe when it is out on the floor and make a cardboard template of the shape that I have to cut from the inner wing so that I can cut it before I fit the engine back in.I also have to cut a small piece out of the cam cover to get it to fit back on.

Real Clubmans have a square nose.Seriously.

- Kenneth Murphy

- NON Member

- Posts: 1515

- Joined: Mon Sep 14, 2009 8:34 pm

- Whats your location?: knockbine

tullycanna

ballymitty

co. wexford. - Region: Eastern

- What Minis have you?: 1972 pick up

1979 leyland

88 designer - Location: south east region

- Contact:

Re: 1275GTi conversion

damn your neat i'd have [edited for inappropriate] it in as was and cut lumps outta sometin, like i did with my 16v project,(i will add that it didn't work, maybe i'll copy you and be neater)

Re: 1275GTi conversion

Just a silly question, but with the alternator mounted that way (therotical backwards) will it not turn in the wrong direction? Will that effect the charging circuit, or is it ok in both directions?

-

kerryminigringo

- IMOC Paid Member

- Posts: 2680

- Joined: Thu Feb 10, 2005 9:44 pm

- Whats your location?: Between an A series and a G13B

- Region: Eastern

- What Minis have you?: 61 van,68 MKII,

75 Clubman estate,

80 1275GT

91 RSP Cooper - Location: Between an A series and a G13B

- Contact:

Re: 1275GTi conversion

An alternator is basically a 3 phase motor with a retifier circuit attached to the output so unless you change the electrical connections the output will be the same.Changing the direction of a 3 phase motor requires you to change over two windings so unless this is done the output will remain the same.

Real Clubmans have a square nose.Seriously.

Re: 1275GTi conversion

Righto that answers that,

-

kerryminigringo

- IMOC Paid Member

- Posts: 2680

- Joined: Thu Feb 10, 2005 9:44 pm

- Whats your location?: Between an A series and a G13B

- Region: Eastern

- What Minis have you?: 61 van,68 MKII,

75 Clubman estate,

80 1275GT

91 RSP Cooper - Location: Between an A series and a G13B

- Contact:

Re: 1275GTi conversion

I made a start on measuring the drive shafts.The guys over on the 16v Mini forum use a timber dowel and mark where it goes into the cv joint through the travel of the suspension and work off the longest measurement.I decided to use a piece of 20mm copper bar and made up two pieces of aluminium which I held in place with two Jubilee clips.The reason I am using the Jubilee clips is that I will be easily able to move the pieces of aluminium and move them so that the touch the cv joint at the longest point.Here is the bar with the Jubilee clips holding the aluminium brackets.

Here is a picture of the bar in place at the Mini hub side with the aluminium touching the cv cage.

And at the other Suzuki end which has a lot of adjustment as the cage can move about 60-70mm in and out.

I put a hacksaw mark on the bar and then used the clips and brackets to measure the drivers side.There will be about 15-20mm diference in the lenght of the shafts and the it is at the bottom of suspension travel that the shaft travel was the longest.By working back from that mark I can figure out where the circlip groove is.

Next up will be to get the shafts made up.I also made a cardboard template of the hole I have to cut out of the inner wing to allow the alternator to fit.I put two black marks along the bottom so that when I fit the subframe I can line up the template and mark the hole for cutting.

I also changed the fuel pipes for better MPI ones as I had made the return from copper and I was not happy with the fit so that job is finished and the tank all plumbed in.The handbrake cable and lever were also fitted so next will be to get tabs welded on the front frame for brake pipes and get it powder coated.

Here is a picture of the bar in place at the Mini hub side with the aluminium touching the cv cage.

And at the other Suzuki end which has a lot of adjustment as the cage can move about 60-70mm in and out.

I put a hacksaw mark on the bar and then used the clips and brackets to measure the drivers side.There will be about 15-20mm diference in the lenght of the shafts and the it is at the bottom of suspension travel that the shaft travel was the longest.By working back from that mark I can figure out where the circlip groove is.

Next up will be to get the shafts made up.I also made a cardboard template of the hole I have to cut out of the inner wing to allow the alternator to fit.I put two black marks along the bottom so that when I fit the subframe I can line up the template and mark the hole for cutting.

I also changed the fuel pipes for better MPI ones as I had made the return from copper and I was not happy with the fit so that job is finished and the tank all plumbed in.The handbrake cable and lever were also fitted so next will be to get tabs welded on the front frame for brake pipes and get it powder coated.

Real Clubmans have a square nose.Seriously.

Who is online

Users browsing this forum: No registered users and 8 guests